Upgrading pipelines releases green energy

Tap potential to create lean benefits

Hebei Xinda Steel Group Co., LTD

Raw material factory

In the entire process of steel production, dust control in the raw material handling stage is not only a key focus of environmental protection efforts but also a potential "rich mine" for cost reduction and efficiency improvement. The lime workshop of the raw material plant of Hebei Xinda Steel Group Co., Ltd. focused on the pain points such as unreasonable design of dust removal pipelines and waste of air volume. Taking lean improvement as the key point, through a "small investment, big effect" pipeline optimization and transformation, it not only achieved a transformation of the on-site environment to "no visible smoke and dust", but also achieved an outstanding annual cost reduction of over 100,000 yuan. Inject green impetus into the high-quality development of the group.

Face the pain points directly

The air volume problem hidden in 52 suction points

To thoroughly address the smoke and dust issues at five key positions in the production site of the lime workshop, including the tail end of the pit and the discharge port of the vibrating screen, the section promptly established a lean research team. Through on-site investigation, data monitoring, and all-staff discussions, the root causes of the problems were gradually identified: Among the 52 dust collection points, some pipelines were blocked by debris, resulting in a reduction in air volume. The manual valve control at the dust collection points of the feeding trolley was not timely, causing a waste of air volume. The large span and numerous corners of the main pipelines led to the accumulation and retention of dust. The superimposition of the three core issues has reduced the originally abundant dust removal air volume, which not only affects the environmental protection effect but also increases the energy consumption of the equipment.

Precise policy implementation

Three renovations cracked the dust removal code

Do not blindly increase the air volume. Every bit of wind force should be used where it is most needed. The research team established the renovation concept of "targeted governance and minimum investment", formulated special plans for three key issues, and solved the dust removal problems one by one.

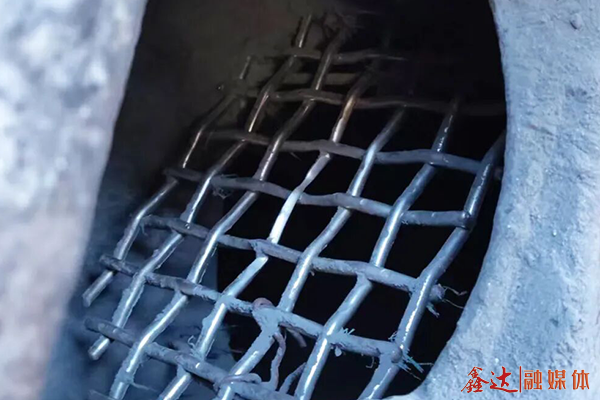

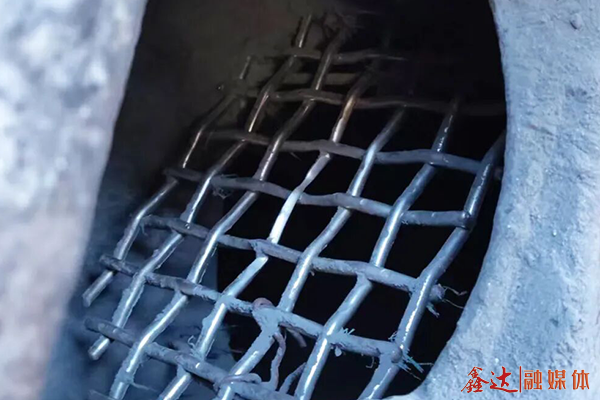

In response to the problem of material debris blocking the pipes, the team conducted multiple experiments and ultimately chose to install 20mm detachable filters at all 52 dust collection points. 10mm filters are prone to clogging and require frequent cleaning, while 20mm filters can effectively intercept debris while ensuring smooth air flow. At the same time, the cleaning system for each shift should be clearly defined, with the class monitors of the three shifts taking turns to conduct inspections to ensure that the filter screens are always in a highly efficient filtering state. After the renovation, the situation of debris entering the pipeline was reduced by more than 95%, and the ventilation efficiency of the pipeline was significantly improved.

In response to the issue of untimely control of the dust collection points, the team upgraded all five manual dust collection valves of the feeding trolley to DN350 pneumatic valves and linked them with the trolley operation system: the valves automatically open within 10 seconds of the trolley discharging materials and automatically close during the 180-second operation period. This renovation has completely solved the waste problem caused by idle vacuum cleaning. Just this one aspect has saved nearly 30% of the ineffective air volume consumption, and the wind force at other vacuum cleaning points has also been increased accordingly.

In response to the problem of dust retention in the pipeline, technicians installed DN100 cleaning valves at 10 corners of the main pipeline and established an operation standard of "cleaning for light accumulation once a week and for severe accumulation once a shift" : when the air volume is insufficient, open the valve to introduce high-pressure air to carry away the accumulated dust by the airflow. When the blockage is severe, manual cleaning should be carried out through the valve. This design not only avoids the high cost of large-scale pipeline demolition and modification, but also makes the daily maintenance of the pipeline simple and efficient. The inner diameter of the main pipeline always remains at the standard size, and the problem of air volume attenuation is easily solved.

Double the benefits

Small renovations bring "big returns"

The total investment in the three renovations was only 18,500 yuan, yet it achieved a triple harvest of environmental benefits, economic benefits and social benefits.

In terms of environmental protection effects, all five smoke and dust overflow points before the renovation have been eliminated. The site has achieved "no visible smoke and dust", the air quality at the post has significantly improved, the labor intensity of the employees has been greatly reduced, and the section has been awarded the title of "Environmental Protection Demonstration Post" by the company.

From an economic perspective, after the renovation, the operating frequency of the dust collector has been reduced from 45Hz to 35Hz, still meeting the on-site dust removal requirements. For every 1Hz reduction, 3.6 kilowatt-hours of electricity are saved per hour. It is estimated that the annual electricity cost savings exceed 130,000 yuan, and the annual net profit creation exceeds 101,000 yuan.

From the perspective of management benefits, the team simultaneously formulated two standardized documents, namely the "Dust Collection Point Inspection System" and the "Pipeline Cleaning Method", clearly defining the management mechanism of "inspection by shift, review by week, and assessment by month", solidifying the renovation results into a long-term system and providing a replicable "Xinda Experience" for the subsequent operation and maintenance of environmental protection facilities.

Conclusion

Upgrading pipelines to unleash green energy and tapping potential to create lean benefits. The lime workshop has leveraged "minor renovations" to drive "major improvements", not only adhering to the bottom line of environmental protection but also meticulously calculating the details of benefits. This vividly demonstrates that cost reduction and efficiency enhancement do not require large investments, and there is room for lean improvement everywhere. In the future, the raw material factory will always adhere to the development concept of "environmental protection first and efficiency as the foundation". From equipment operation and maintenance to process optimization, from on-site management to cost control, it will continuously explore the "hidden value" in production and operation, transform every optimization into development effectiveness, and enable green and low-carbon development and quality improvement and efficiency enhancement to mutually empower each other, writing more brilliant answers for Xinda's high-quality development!

Email

Email Email

Email